Break bulk vs cross docking is a recurring choice for logistics managers. Break bulk handles oversized freight, while cross docking moves goods quickly with little or no storage. The method you choose affects cost, cargo safety, and delivery performance across an entire supply chain.

What Is Break Bulk Shipping?

Break bulk shipping moves freight that cannot fit into a container or standard palletized unit. This approach dominated before containerization and still matters when cargo is oversized or irregular in shape. Construction equipment, turbines, steel beams, and other heavy pieces often fall into this category.

The process involves unloading goods individually at the port and transferring them directly for storage or onward movement. Break bulk also offers flexibility at ports that lack specialized container infrastructure. And in some cases, it allows single pieces to reach destinations without waiting for consolidation into a container load.

Drawbacks of Break Bulk

Because each piece must be handled separately, labor and handling costs rise compared to containerized freight.

- Every extra touchpoint introduces another chance for damage or loss.

- Scheduling can also be tricky, since vessels carrying break bulk cargo need specialized arrangements and may spend longer in port.

Even with these challenges, break bulk remains essential for industries moving oversized or high-value equipment. For project cargo, energy infrastructure, and heavy construction, it often stands as the only workable option. That’s why managers weighing break bulk vs cross docking must start with cargo type.

What Is Cross Docking?

Cross docking is built on speed and minimal storage. In this setup, inbound freight arrives at a facility, is unloaded, sorted, and quickly transferred onto outbound trucks. The goal is to minimize dwell time and cut out warehouse storage whenever possible.

For retailers, e-commerce companies, and fast-moving consumer goods, cross docking creates agility and helps keep shelves stocked or customer orders fulfilled without delay. Its success depends on precise scheduling, integrated tracking systems, and reliable dock operations. When those align, freight can move from inbound to outbound within hours instead of days.

Advantages and Limits of Cross Docking

Cross docking shines in industries where speed sets the competitive edge. Cutting inventory holding costs and removing storage steps can make a big difference for high-volume distributors. With fewer touchpoints, the chance of product damage also drops — a key advantage for perishables and consumer goods.

Still, the system has limits. It doesn’t work well for irregular or oversized freight, and it requires tight coordination among carriers, shippers, and warehouse operators. Inbound delays can ripple through the schedule, creating bottlenecks. Without strong technology and planning, the model stalls. For companies comparing break bulk vs cross docking, speed often tips the scales toward cross docking.

Break Bulk vs Cross Docking: Key Differences

Comparing break bulk vs cross docking shows just how different the two methods are at their core.

- Break bulk focuses on oversized or unconventional cargo that cannot be containerized.

- Cross docking centers on time sensitivity, serving industries where fast transfer beats long-term storage.

- Costs diverge as well. Break bulk usually runs higher due to labor and special handling, while cross docking reduces warehousing but requires investment in coordination systems.

- The risk profile is also different: break bulk raises damage concerns with frequent handling, while cross docking depends on schedules that can break down if timing slips.

For logistics managers, the question becomes whether cargo type or delivery speed carries more weight.

Industry Applications

Different industries rely on break bulk and cross docking in very different ways.

Heavy Industry and Infrastructure

In practice, break bulk serves industries like construction, oil and gas, and large-scale infrastructure. Moving turbines, bridge sections, or drilling rigs simply isn’t possible in containers, making break bulk the only choice.

Retail and Consumer Goods

Cross docking dominates in retail distribution, electronics, pharmaceuticals, and consumer goods. A major retailer may move goods directly from supplier trucks to outbound trailers headed to stores, bypassing warehouse storage. For e-commerce, cross docking supports same-day or next-day delivery by keeping dwell time near zero.

Specialized Sectors

Other sectors also benefit. Aerospace shipments often use break bulk for oversized aircraft components that demand special handling, while agriculture distributors lean on cross docking to move perishable produce quickly through regional hubs. By including both ends of this spectrum, the two methods cover heavy industrial demand on one side and time-sensitive consumer supply chains on the other.

Choosing the Right Method

Several factors influence whether break bulk or cross docking is the right fit, and managers need to weigh them carefully.

Cargo Priorities

The choice between the two methods depends first on supply chain priorities. If the freight itself dictates the approach — like oversized machinery — break bulk is unavoidable. If speed is the driver, cross docking is the clear pick.

Cost and Risk Considerations

Cost also matters. Break bulk involves more manual handling, while cross docking trims storage but demands strong scheduling systems. Managers must also consider risk: will the bigger challenge be cargo damage from handling, or delays caused by poor dock coordination?

Role of Technology

Technology increasingly shapes the decision. Companies with advanced warehouse management systems (WMS) or transportation management systems (TMS) may favor cross docking, since real-time data smooths scheduling and reduces risk. Firms without that infrastructure may default to break bulk, where manual handling remains the core process. Ultimately, break bulk vs cross docking decisions come down to size versus speed. And that’s the trade-off every supply chain team has to measure.

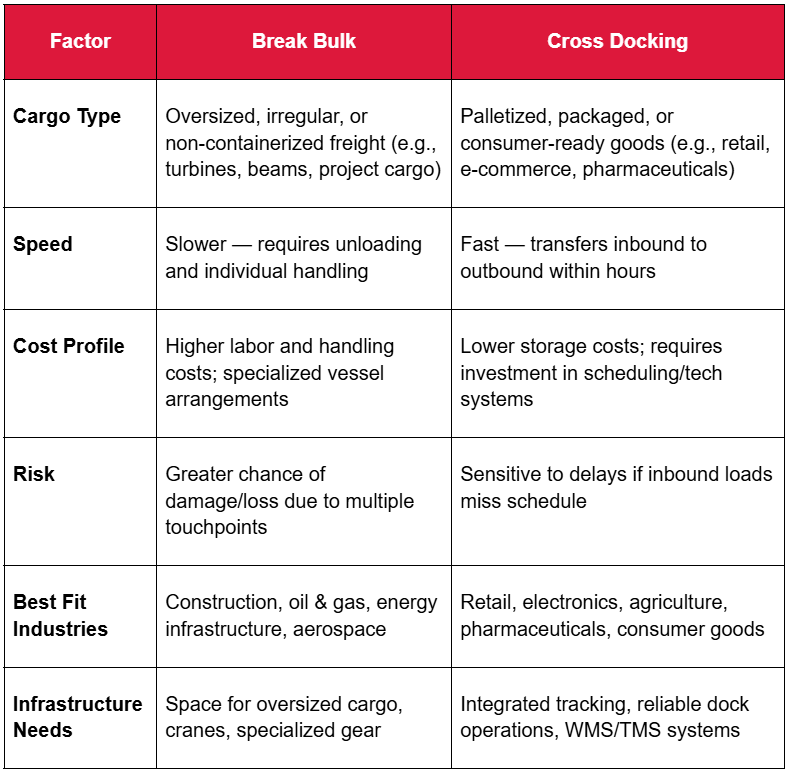

Break Bulk vs Cross Docking: Quick Comparison

How Cross Docks & Storage Supports Both

Cross Docks & Storage supports both methods with the right facilities and equipment. For break bulk, that means the space and gear to manage oversized freight efficiently.

For cross docking, it means streamlined transfers, advanced tracking, and minimal touchpoints that keep freight moving. Having both options under one roof lets customers adapt their supply chains while counting on reliability from a proven partner.

Partner with Cross Docks & Storage for Smarter Freight Transfers

We provide specialized space and equipment to support both break bulk and cross-docking operations. Our facilities are designed for minimal touchpoints, fast transfers, and dependable tracking systems that keep cargo moving on schedule. Contact us today for more information.